Stansted Homogenising Systems

Stansted Homogenising Systems Limited is a UK-based company located in Essex, specializing in the design and manufacture of ultra-high pressure homogenizers. Their equipment operates at pressures up to 60,000 psi (4200 bar), and is widely used across industries such as biotechnology, pharmaceuticals, and food processing—for applications including cell disruption, protein extraction, and nanoemulsion preparation.

Common Applications Include:

-

Cell Disruption / Lysis – aligned with fermentation and bioreactor processes.

-

Particle Size Reduction – relevant to the particle sizing instrument market.

-

Food Preservation & Modification – corresponding with conventional mixers and particle sizing applications.

The company offers a wide range of scalable solutions—from laboratory scale to full industrial production—equipped with temperature control and a variety of valve configurations to ensure process flexibility and efficiency.

With over 45 years of expertise in high-pressure fluid processing, Stansted Homogenising Systems emphasizes durability, safety, and ease of maintenance. Their products are constructed using pharmaceutical-grade stainless steel and high-performance polymers, and are equipped with electronic controls and digital pressure displays to ensure consistent and precise processing conditions. Backed by a global sales and service network, the company is committed to delivering customized homogenization solutions that meet demanding process requirements while reducing operational costs.

Stansted Homogenizing Systems' Product Traits

-

Patented Design - The Hyd-Lok system uses hydraulic clamping instead of bolts to hold the intensifier together. You can open it with one button—no tools needed—making cleaning and maintenance quick and easy.

-

Reliable and Durable - A strong electro-hydraulic system powers one or two synchronized intensifiers. With just 2–12 strokes per minute, wear on parts is minimal, ensuring long life and low maintenance costs.

-

Easy to Use - A PLC control system shows temperature and pressure and lets operators run the machine and check for issues through simple menus. It can also connect to a computer or data logger.

-

Temperature Control - The system supports pre-cooling, pre-heating, post-cooling, and keeping the process at a constant temperature.

-

Easy Maintenance - All parts in contact with the product are easy to take apart, clean, inspect, and put back together.

Laboratory High Pressure Homogenizer

Our laboratory high-pressure homogenizer offers a range of features designed for versatility and ease of use. It supports continuously adjustable pressures from 100 bar (1,500 psi) up to 4,200 bar (60,000 psi), making it suitable for processing various cell types and materials. The system operates in both continuous and single-shot modes, including for highly viscous formulations, with flow rates adjustable in small milliliter increments up to 275 mL per minute. It comes with interchangeable processing cells in 1 mL, 5–9 mL, 16 mL, and 32 mL sizes, and offers multiple temperature control options, including rapid cooling and pre-heating. The unit is designed for ease of operation, cleaning, and sterilization, supporting both CIP (Clean-in-Place) and SIP (Sterilize-in-Place), and is easy to maintain.

Pilot-Scale High Pressure Homogenizer

Fully featured system with a processing capacity of up to 130 liters per hour. Delivers continuous and smooth output, with optional piston gap and micro-channel processing technologies.

-

The 7400 Pilot Series is ideal for users looking to scale up from laboratory models to higher throughput systems.

-

The 7575 Pilot Series is designed for users planning to transition from pilot-scale to full production-scale operations.

How It Works - A Quick Look at Its Mechanisms

A. Types of conventional equipment and their primary working mechanisms include:

-

Stirrer: Primarily relies on shear force (Shear)

-

Agitator: Mainly generates shear force (Shear)

-

High Shear Mixer: Provides intense shear action (Shear)

-

Ultrasonic Mixer: Uses cavitation effect (Cavitation) for mixing

-

Bead Mill: Operates through impact force (Impact)

-

High-Pressure Homogenizer: Combines shear force, cavitation, and impact (Shear, Cavitation & Impact) to achieve highly efficient homogenization

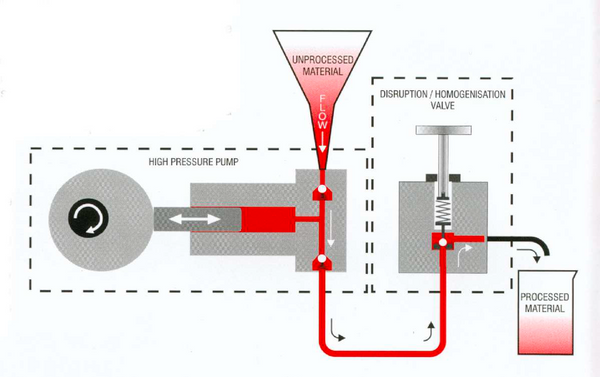

B. What is a high-pressure homogenizer?

1.

2.

-

High Pressure Pump - A high-pressure pump generates high pressure, either a piston plunger pump or a hydraulic intensifier pump.

-

Homogenizing Device - A high-pressure homogenizing device converts pressure energy into smaller particles or is used for cell disruption, using either a valve-type device or a fixed-orifice device.

C. High-Pressure Pumps

Two basic types of pumps and their respective advantages and disadvantages:

-

Piston Plunger Pump – typically driven by a crankshaftAdvantages:

-

+ High efficiency

-

+ When equipped with three or more pistons, it delivers relatively smooth flow to the homogenizing valve

-

+ Lower cost

-

- Limited reliability at high pressures

-

- Commonly used in dairy processing at 35 MPa (350 bar)

-

- Generally applicable up to 100 MPa

-

- Not suitable for high-viscosity fluids when piston speed is too high

-

- Not well suited for use with fixed-orifice devices

-

- Reliability decreases as pressure increases, with fatigue and wear becoming more significant

-

- Laboratory applications typically do not exceed 200 MPa; production applications usually remain below 150 MPa

-

-

Hydraulic Intensifier Pump – typically hydraulically driven

-

+ Operates at low speed (fewer fatigue cycles)

-

+ Better suited for high-viscosity fluids (as long as the return stroke is slow enough to avoid cavitation)

-

+ Can achieve higher pressures (400 MPa; HS systems up to 1400 MPa)

-

- Relatively higher cost

-

- Compared to a simple motor and crank system, intensifier pumps require a motor, hydraulic pump, and control valves, making the setup more complex

-

Intensifier pumps are a critical component of high-pressure homogenizers. They drive the product forward under constant pressure through fixed-geometry microchannels in the chamber. This high pressure generates high flow velocity, which in turn creates strong shear and impact forces to achieve the desired particle size.

D. Homogenizing Devices

Overview of the two main types of homogenizing devices:

-

Piston Gap

-

Traditional type

-

Reverse flow design, also known as the Stansted valve

-

-

Fixed Orifice / Micro-Channel Type

-

Interaction Chamber

-

Piston Gap – Uses high pressure to force liquid through a narrow gap between the piston and homogenizing valve, generating strong shear and cavitation effects to reduce particle size and achieve thorough mixing.

Characteristics of the Two Main Types of Homogenizing Devices

-

Piston Gap

-

The liquid is delivered at full flow directly from the pump.

-

The gap adjusts automatically based on pressure, flow rate, and viscosity.

-

Performs well with certain products, but generally not as effective as the Interaction Chamber in achieving ultra-fine particle sizes.

-

Unlikely to clog.

-

Difficult to scale up reliably for particle size reduction applications, but performs consistently and reliably in cell lysis processes.

-

Mechanism: High pressure forces the liquid through a narrow gap between the piston and homogenizing valve, generating strong shear and cavitation forces to reduce particle size and achieve effective mixing.

-

-

Fixed Orifice / Micro-Channel Type

-

Flow through each microchannel is limited and affected by pressure, flow rate, and viscosity.

-

Generally the preferred technology for achieving the smallest particle sizes.

-

More prone to clogging.

-

Easier and more predictable to scale up by adding additional microchannels.

-